Pre-treatment is the first step in the brush conformal coating process. This involves the operator ensuring the surface is clean and debris-free. Once completed, the correct brush applicator is selected; a soft-bristled brush is ideal for thin-film coatings, while a stiff-bristled brush is recommended for thicker coats. Testing the brush for compatibility is essential for getting the best results.

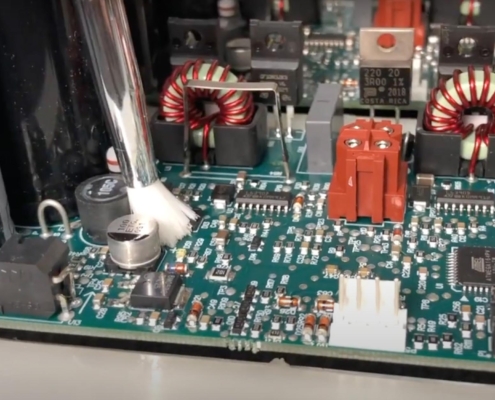

After finding the right brush, the operator applies the conformal coating layer. This step includes dipping the brush in the material and carefully applying it to the substrate, ensuring the correct areas are covered. Sometimes multiple coats are required to achieve even coverage and maximize protection. After application, the user uses a clean cloth to remove any excess material from the PCB.

Finally, the operator cures the PCB to meet their exact specifications. This process is done by baking or air drying the components at high temperatures to verify the coating material is dry and adequately protects the board.